My Blog

Low Temperature Differential Stirling Engine: Making the Plates

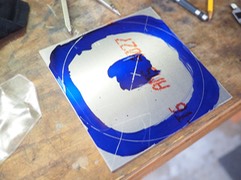

The next parts I made for my Stirling engine were the top and bottom plates. These plates are structural, where many assemblies are attached, though they also function as a conductor for the heat source.

I layed out the circles on 1/4” thick aluminum square with layout fluid and a protractor, then cut them out with a jigsaw:

Next, I cut a circle out of scrap wood with roughly the same dimensions and mounted it on a plate to attach to my lathe:

To clean up the edge of the aluminum circle, I centered and mounted it on the wooden arbor with double-sided duct tape (after I was done I removed the aluminum by heating up the adhesive with a blow torch so it would become looser).

…