From the outset of the KFETS project, my client knew that he wanted it to be as sturdy and unbreakable as possible. To ensure this, I searched for “milspec” (military specifications) parts. The two parts which I focused on were the ones that would endure the most abuse: the mode switcher and the central switch.

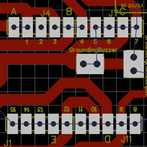

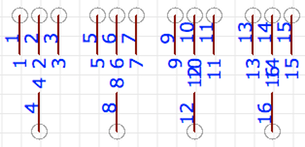

Above: the central switch in my PCB and schematic:

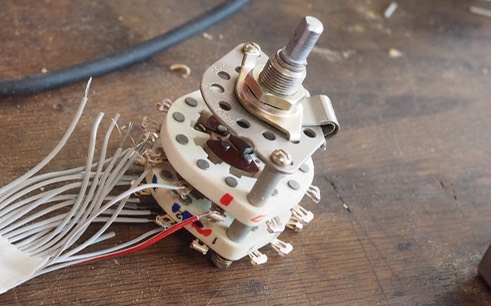

I designed the central switch to be a 4-pole, 3-position rotary switch. Any 4p3t switch with military specifications available online was out of my price range. So, we went to eBay! For a fraction of the price, we were able to secure four strong rotary switches from Russia.

Pictured above: thin ribbon cable mid-solder to the heavy-duty switch (before I realized what a terrible idea this was and redid it with much lower gauge wire!)

The mode switcher provided more issues during the project. It arose as a means to fix shorting issues which I had been experiencing since one of the first revisions. At first, I thought I needed a 3 position toggle switch, but after the size I needed proved nearly impossible to find, I realized that I could do the same thing with a much cheaper and available 2-position, 6-pole toggle switch, which was also very stable.

Below: a sneak peek of the toggle switch in the final lid, and the toggle switch in my PCB layout (as you can see, only 12 pins are used, allowing me to use an 18-pin switch instead of a 4-pole 3-position toggle switch! Man, did that take forever to realize…)