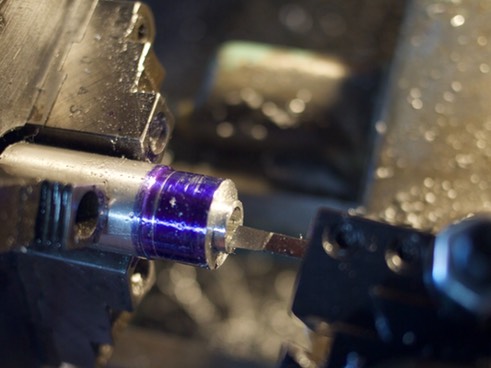

The clear flywheel is mounted on the flywheel hub, which fits around one side of the crankshaft. It is made on the lathe from aluminum.

First, I drilled a hole in the aluminum to stabilize it with a live center while I cut it down:

I marked all the distances with my calipers and cutoff saw and then I cut the notch down.

I then began the process of hollowing out the center of the part, first gradually stepping up drill bit diameter (large enough to insert my lathe bit) then cut out the portion slowly with autofeed. To assist me, I used an analog gauge to check depth by setting the surface of the part at 0” and slowly moving the carriage inwards to the proper depth.

I cut off the part and added a chamfer. I drilled and tapped a side hole for mounting the hub on the crankshaft:

The part was finished!