The next step in building the Stirling Engine was to craft the base block. It attaches the cylinder to the chamber and attaches to the bearing plate. I cut the base block from a rough block of aluminum.

I put the rough block into the four-jaw chuck on the lathe to square up the sides:

Now with the properly-sized block, I layed out the cuts with the layout fluid (here you see the properly-sized block next to the original block):

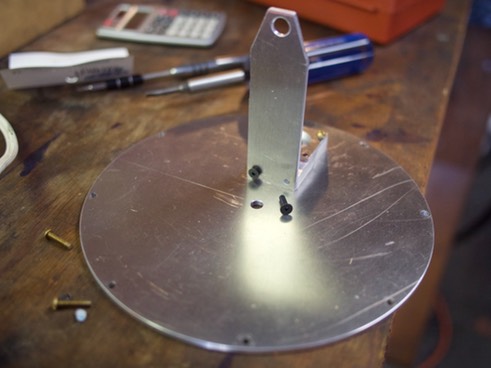

I then lined up and taped the bearing plate to the base block, centered the drill bit, then cut a blind hole into the base block. I then used a tap to cut a threaded hole.

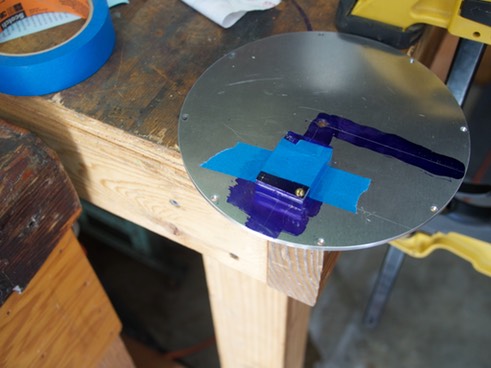

Then, I drilled the holes to attach to the top plate by lining up the block on the top plate, taping them together, and drilling through:

Finally, I drilled out the center hole, starting with a small bit and slowly increasing in size until the proper diameter was reached.

The base block was finished!