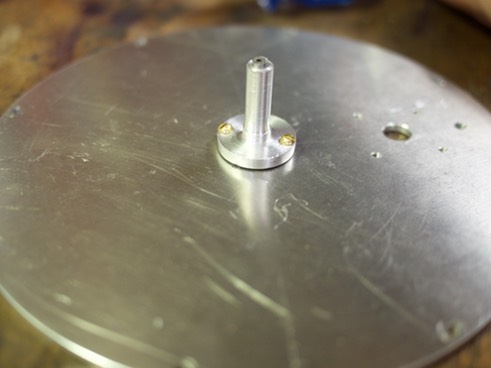

Continuing on my Stirling Engine, I built the displacer bushing. The shaft of the displacer is stabilized by the displacer bushing, which attaches to the top plate.

The bushing was cut from a 1” thick cylinder of aluminum and a steel insert. I put the aluminum into the three-jaw chuck on the lathe and roughed out the shape with the power-drive and cut off the part:

Next, I shaped the steel insert.

Then, I cut it off, and glued it in place. The reason for this insert is that when brass (used for the displacer shaft) rubs against aluminum, it “galls”, or increases in friction and adhesion making it very difficult for the shaft to slide. However, brass and steel do not gall.

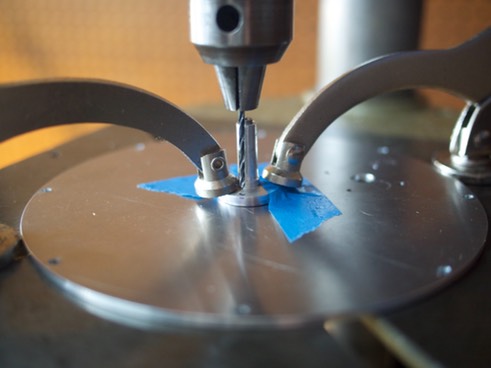

Finally, I aligned the part on the top plate and drilled the side holes.

The displacer bushing was finished!